Application: Mainly used in petrochemical, electric power, paper, tobacco, building heating and other industries such as air cooler, air heater and food industry plant protein powder, starch and other spray drying system of air heaters.

Working temperature: 230 ℃, using the most advanced CNC L finned pipe through digital control to keep segment binding force in the best condition, rolling forming of the trapezoidal cross section and the heat flux density distribution in size, on the basis of material saving, greatly improving the thermal efficiency, put an end to the string type finned tube for segment gap cannot eliminate the contact thermal resistance.

(1) Features: the winding process, high production efficiency, is apart from the uniform, good heat transfer, wing than high, base tube can be protected from air erosion.

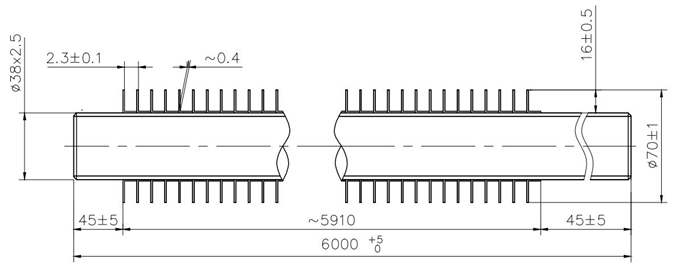

(2) The samples structures is like this:

| TYPE | NAME | BARE TUBE MATERIAL | FIN TUBE MATERIAL | BARE TUBE DIAMETER(MM) | FIN SPECIFICATION(MM) | ||

| FIN PITCH | FIN HEIGHT | FIN THICK | |||||

| WOUND | L/KL/LL TYPE FIN TUBE | CARBON STEEL,COPPER, STAINLESS STEEL,ALLOY | COPPER ALUMINUM | 16-63 | 2.1-5 | ?17 | ~0.4 |