Plastic Saddle Rings are a versatile and economical industry standard with well-known performance characteristics. Low pressure drop, high flux, high efficiency , easy to handle.

Applications: Absorption, scrubbing, and stripping services; Pulp and paper service, such as bleach plant absorbers;Versatile alternative to ceramic saddles.

Performance:

Good capacity and low pressure drop.

Higher capacity and lower pressure drop than ceramic saddles.

Multiple sizes provide ability to optimize capacity and efficiency based on application requirements.

Higher liquid hold-up and residence Time.

Relatively high liquid hold-up allows good absorption efficiency with slow chemical reaction.

Versatile standard packing.

Lower sensitivity to liquid and vapor distribution quality allows use with conventional liquid distributors.

Specification:

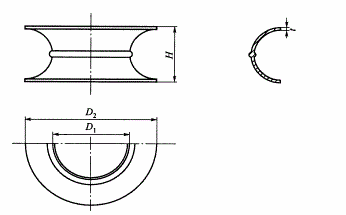

| Diameter (mm) | Size (mm) D1x D2 x H x t | Surface Area (m2/m3) | Void Rate (m3/m3) | Number PCE/M3 | Weight Kg/M3 | Dry Packing Factor (m-1) |

| 25 | 25×38x19x1.2 | 258 | 89 | 84000 | 100 | 366 |

| 38 | 38×60x30x1.2 | 170 | 91 | 25000 | 81 | 226 |

| 50 | 50x80x40x1.5 | 120 | 92 | 9300 | 72 | 154 |

| 76 | 76x114x57x2.5 | 105 | 93 | 1800 | 63 | 131 |